Understanding the Basics

Ever felt your vehicle’s brakes fading under heavy loads or extreme conditions? Or perhaps you’ve heard about specialized engineering techniques that improve brake performance for off-road adventures, long hauls, or even everyday driving. Well, this article dives into the fascinating world of “tie down engineering brakes,” a field where meticulous attention to detail and cutting-edge innovations go hand in hand to ensure safety, efficiency, and optimal control on any road.

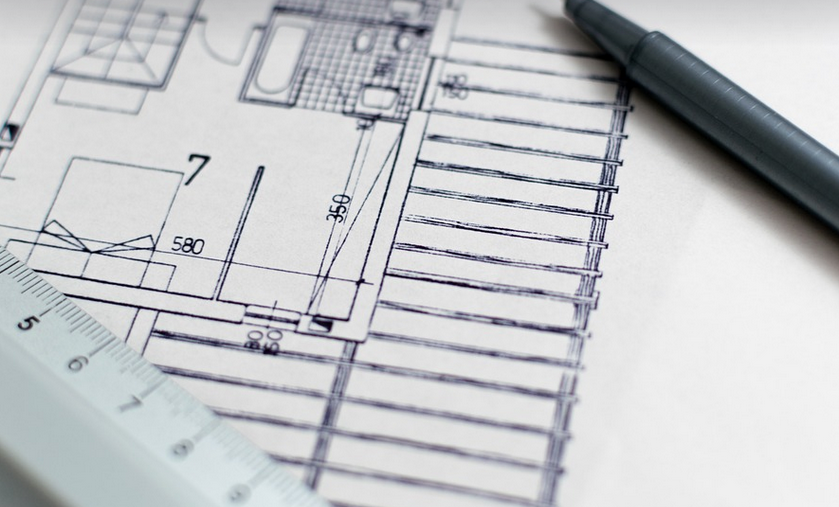

At its core, tie down engineering brakes involves optimizing brake systems for specific use cases. It’s not about simply adding more power or bigger parts; it’s about understanding how different factors impact braking performance – weight distribution, load capacity, terrain, weather conditions, even driving style – and then tailoring the brakes to meet those requirements.

Behind the Wheel: Why Tie Down Engineering Matters

Imagine this: you’re towing a heavy trailer across a mountain pass. Without proper brake adjustments, your vehicle may struggle with stopping power on steep inclines or during sudden braking maneuvers. The same goes for transporting bulky loads in extreme weather conditions – these situations call for specialized braking solutions to ensure safety and control.

Tie down engineering brakes aim to address these challenges by incorporating clever engineering principles and advanced materials:

- Customizable Braking Systems: Engineers can tailor brake pads, rotors, calipers, and hydraulic systems to match the specific requirements of each vehicle and its intended use.

- Advanced Materials: High-strength alloys and advanced composite materials are often used for components, leading to increased durability, heat resistance, and lighter weight for improved performance.

- Precise Tuning & Calibration: Engineers meticulously calibrate brake systems based on vehicle weight, load capacity, and driving conditions. This ensures optimal braking efficiency at all times.

Key Components of Tie Down Engineering Brakes

Let’s take a closer look at the vital components that make tie down engineering brakes so effective:

**1. Brake Pads:**

These are the crucial contact points between the brake caliper and the disc. They come in different materials, each offering unique advantages: from high-friction organic compounds for everyday driving to racing-grade friction modifiers that deliver maximum braking power. Choosing the right pad material depends on factors like expected operating conditions (heat, wetness, dust, etc.), weight of the vehicle and driver, and desired stopping distance.

**2. Brake Discs:**

These are the metal discs that wear against the pads to generate friction for braking. Disc types vary in size, material thickness, and heat dissipation capabilities:

- Steel Disc Brakes: These offer affordability and durability but may require more maintenance than alloy versions.

- Alloy Disc Brakes: Known for their lightness, strength, and improved heat resistance.

- Carbon-Ceramic Disc Brakes:** These top-tier options boast exceptional performance with minimal thermal transfer and highly efficient braking.

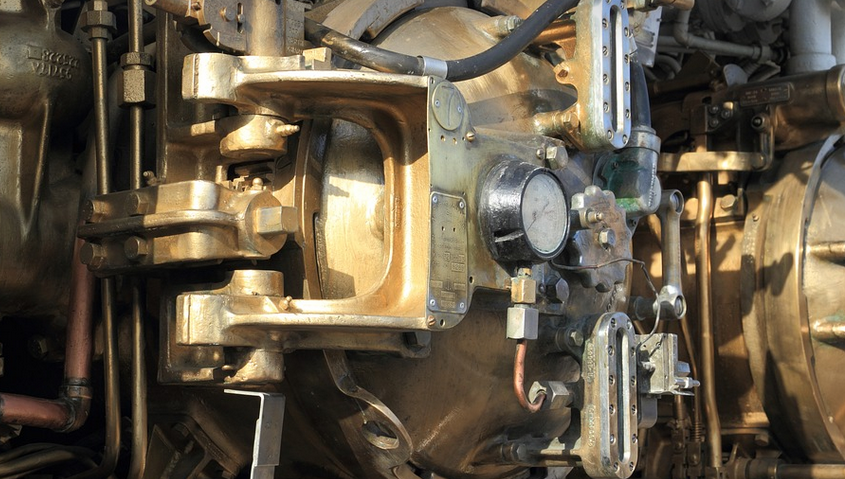

**3. Brake Calipers:**

These crucial mechanisms apply force on the brake pads, ensuring consistent pressure on the discs for maximum stopping power:

- Caliper Design and Material: Caliper design significantly impacts braking efficiency and durability. Advanced designs incorporate features like adjustable pistons, multi-piston calipers, and floating caliper systems to increase precision and control.

* **4. Hydraulic System:** This intricate network of hoses, valves, and reservoirs delivers the fluid pressure needed to actuate the brake pads against the discs. Efficient hydraulic systems minimize wear and tear on components and ensure consistent braking force under all conditions.

The Benefits of Tie Down Engineering Brakes

Why bother with tie down engineering brakes? The benefits go beyond just stopping power.

**Improved Safety:**

By adjusting brake systems for specific situations and needs, you can significantly reduce the risk of accidents caused by inadequate braking. Advanced braking systems ensure smoother stops, increased control over your vehicle, and improved performance even during demanding maneuvers.

**Enhanced Efficiency:**

Tie down engineering brakes optimize power delivery and braking efficiency, saving fuel in the process. This means longer ranges on a single tank, fewer stop-and-go situations, and less stress on your engine.

**Extended Lifespan:**

Specialized brake components made with high-quality materials are designed to withstand demanding conditions and resist wear and tear for extended durations. This translates to less frequent maintenance and a longer lifespan, making tie down engineering brakes a cost-effective investment in the long run.

Exploring Further

This exploration of “tie down engineering brakes” provides you with a deeper understanding of how these advanced technologies work and what they can achieve. If you’re looking to maximize your vehicle’s performance, safety, and longevity in all sorts of conditions, consider exploring the benefits of tie-down engineering brakes.