What’s the Deal with Quality Control Jobs at Warehouses?

So you’re curious about Quality Control—maybe even thinking about a job in a warehouse. You want to know what it actually entails, right? Well, buckle up, because this is more than just “checking things off your list.” Quality control jobs are crucial for ensuring the smooth running of any warehouse, especially in 2024 when everything’s online and getting shipped faster than ever before.

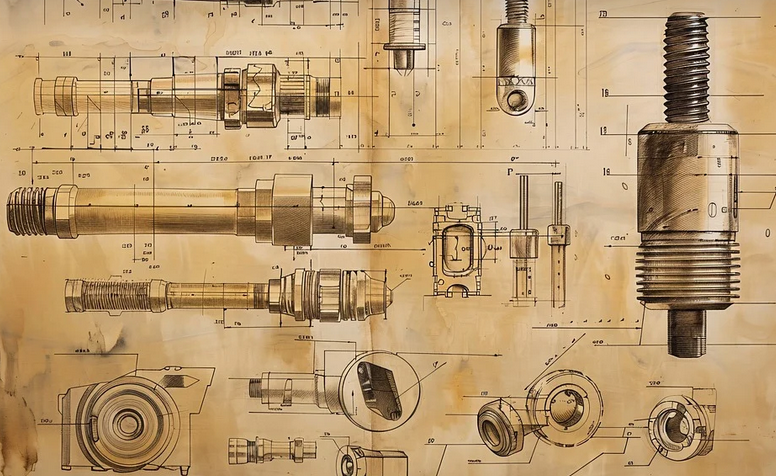

Imagine a giant assembly line humming along, producing goods that will eventually reach you. Every product needs to be checked—this is where Quality Control comes into play. It’s like being the watchdog of the entire warehouse operation, making sure everything meets its standards and hitting those deadlines.

Why Quality Control Matters: More Than Meets the Eye

First off, it’s about consistency. The quality control process ensures that every product leaving the warehouse is exactly as expected. Think of it like this: if you’re buying a shirt, you want it to fit properly and have all its buttons intact, right? That’s what quality control strives for. It avoids mistakes in production or shipping that could lead to unhappy customers.

Then there’s the impact on efficiency. High-quality products mean less time wasted on returns and complaints. This translates directly into lower costs for the company, saving them resources and helping them focus on other priorities. In a sense, quality control is like finding that magic recipe that makes everything run smoother – no more guesswork, just dependable results.

And let’s not forget about safety! Quality control plays a vital role in ensuring the safe operation of the warehouse itself. This might involve checking equipment for proper function or inspecting the environment to make sure it meets safety standards. It ensures everyone’s wellbeing is protected, allowing for a more comfortable working environment.

Behind the Scenes: A Day in the Life of a Quality Control Supervisor

Picture this: You’re standing alongside your team, scanning each product as it rolls off the assembly line. You are the watchful eye, ensuring that every item meets specific standards set for weight, size, and functionality. The speed is constant, but you’ve got to stay sharp.

Quality control supervisors are like the managers of a well-oiled machine – they oversee the entire process. They might be involved in training new recruits on procedures or conducting daily checks on equipment. You’re not just checking things off a list; you’re making decisions that affect the overall success of the warehouse.

But don’t be fooled—it’s more than just sitting at a desk and doing paperwork. Quality Control is about being hands-on, investigating issues on the floor, and communicating with colleagues to address concerns. You’re essentially the problem solver for all things quality.

Beyond the Basics: What Does a Quality Control Job Look Like in 2024?

A modern quality control job is fast-paced and constantly evolving. Technology plays a crucial role, with digital tools becoming increasingly important. Software programs can help analyze data to identify potential issues before they even arise.

In warehouses today, automation is on the rise – everything from guided robots to advanced sensors. These technological advancements require quality control professionals who understand how to operate and calibrate these systems, ensuring smooth workflow. Think of it like putting a puzzle together – you need to know all the pieces and how they fit, and Quality Control plays that critical role.

In the future, there will be more focus on sustainability, especially in an era where environmental consciousness is at the forefront. Quality control professionals will play a role in ensuring products are made using sustainable materials and processes. They’ll also need to ensure compliance with regulations related to waste management and energy efficiency.

Getting Your Foot in the Door: Skills You Need for Quality Control

So, you’re convinced – quality control sounds exciting! Before diving into this career path, let’s chat about some essentials.

* **Attention to detail is key:** Being meticulous and observant is a must. The ability to spot even the smallest imperfections is crucial for quality control.

* **Communication skills are essential:** You’ll be working closely with colleagues, so clear communication, reporting, and documentation are paramount. You need to be able to explain concerns effectively and work as part of a team to solve problems.

* **Problem-solving abilities:** Quality control is about identifying issues and coming up with solutions. You’ll need to be creative, resourceful, and think on your feet to find the most effective way to improve processes.

The Warehouse: A World of Opportunity in Quality Control

So, you’ve seen the possibilities of quality control – it’s more than just a job; it’s about shaping the future of how products get made and delivered.

In conclusion, being a quality control professional is a rewarding career path. It’s challenging, but also exciting, with constant learning opportunities as technology evolves and new challenges emerge. The warehouse industry in 2024 is going through a significant shift, and Quality Control professionals are at the heart of this transformation – ensuring that every product makes its way to your doorstep smoothly, efficiently, and safely.