What are Architectural Millwork Shop Drawings?

Imagine you’re picturing a stunning living room with built-in bookshelves, a unique fireplace mantle, or custom cabinetry. These details are crucial to the final look and feel of a space, but how do we translate those ideas into tangible reality?

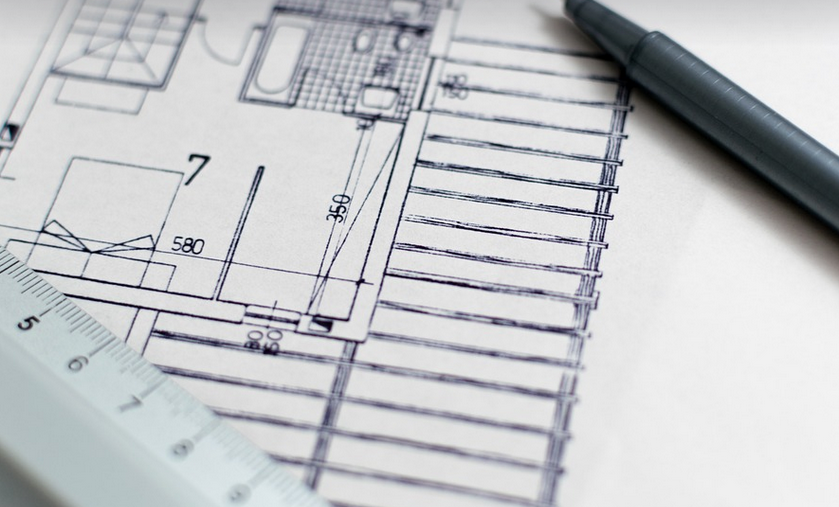

Architectural millwork shop drawings serve as blueprints for all these intricate pieces. They’re essentially visual representations of the building materials, construction methods, and design specifications. They provide detailed instructions for every element of your project, ensuring that each piece is built to perfection.

Think of them as a roadmap for your contractors, guiding them through every step—from cutting wood to assembling intricate joinery. These drawings are essential for communication between architects, engineers, and contractors, minimizing confusion and potential delays on the construction site.

These detailed documents often include multiple plans, elevations, sections, and even exploded views of a particular piece of millwork. They’ll show you how all the pieces connect to create your vision.

For example, imagine a custom staircase. The shop drawings would detail everything – the stair height, tread width, railing design, and even the specific wood species and finishes chosen. They become the reference point for making sure that every step is built correctly.

Why are Shop Drawings Important?

Shop drawings aren’t just about aesthetics; they play a vital role in ensuring your project’s success:

**1. Clear Communication:** Shop drawings act as a single source of truth, eliminating misunderstandings and potential disputes between different parties involved in the project. Everyone is on the same page regarding the specific design and construction methods.

**2. Precise Construction:** By providing detailed instructions, shop drawings ensure that contractors have all the necessary information to construct your architectural millwork precisely and accurately. They reduce the risk of errors or deviations from the desired outcome.

**3. Cost Control:** Shop drawings help project managers estimate material quantities and labor costs effectively, saving time and money in the long run. This allows for better budget planning and potential cost-saving measures throughout the construction process.

**4. Quality Assurance:** Shop drawings serve as documentation for quality control. Contractors can use them to check their work against the original design specifications, ensuring that every piece meets your expectations.

**5. Facilitate Inspections:** Shop drawings help inspectors ensure the construction adheres to building codes and regulations. They provide a clear visual reference point during inspections, increasing efficiency and reducing delays.

**6. Legal Protection:** Shop drawings can serve as valuable legal documentation in case of future disputes or disagreements regarding the final product or construction process.

The Shop Drawing Process

The shop drawing process starts early on in your project’s lifecycle, even before you start working with contractors. It involves a collaborative effort between architects, engineers, and millwork specialists:

**1. Initial Design:** Architects begin by sketching initial design ideas for the architectural millwork, outlining their vision for the finished product.

**2. Detailed Drawings:** Based on those initial sketches, detailed shop drawings are created. These drawings would include technical specifications like dimensions, materials, and joinery methods. They can be simple or complex, depending on the project’s scope.

**3. Collaboration:** This is where communication truly happens. Architects work closely with contractors to review the plans and ensure that everything is feasible for construction. The team might also involve engineers if there are structural components involved.

**4. Revisions and Feedback:** A series of reviews, drafts, and discussions occur until everyone is satisfied with the shop drawings. This ensures a shared understanding before the actual production begins.

**5. Production and Review:** Once approved, contractors receive detailed instructions to manufacture the millwork pieces according to these drawings. The process also involves material sourcing and quality control checks by professionals.

**6. Final Verification:** Before installation, a final review of the shop drawings occurs. This ensures that all details meet the architect’s original vision and that the construction adheres to the agreed-upon specifications.

Shop Drawings: A Matter of Precision

Shop drawings are more than just plans; they are an intricate blend of precision, creativity, and careful communication. They represent a critical bridge between design and construction, guaranteeing that each architectural millwork piece is both aesthetically pleasing and structurally sound.

When working on complex projects, shop drawings play a crucial role in ensuring a successful outcome. These detailed drawings provide the necessary blueprint for contractors to execute the vision of the design, bringing your project to life.

For anyone involved in architectural millwork construction, understanding the importance and intricacies of shop drawings can significantly improve your workflow, enhance communication, and ultimately lead to more satisfying results.

“Well-crafted shop drawings are like a roadmap for building something beautiful,” says Jane Doe, an experienced architect.

“They ensure that we achieve the exact vision we had in mind while maintaining the integrity of the structure. They’re a testament to careful planning and collaboration,” she adds.